There are many materials that can be used to build a board with. The three main board building materials are Baltic Birch plywood, Bamboo and Canadian Maple veneer. Locally grown solid birch veneer is now gaining in popularity, as an alternative to bamboo.

Other materials include solid wood for Vlam (vertical laminated), aluminum and foam-filled carbon fiber composite boards. The most common material used today is Canadian Maple. Finding quality materials to build boards with can be challenging. Big box lumberyards do not carry proper board building materials like 100% Baltic Birch or 1/16″ maple veneer due to the limited uses for the material. Demand for these materials as a home building product is low so specialty shops are usually the only places where they can be found.

Plywood

Plywood is a stack of 3 or more alternating layers of sliced wood veneer glued together. There are many thicknesses, wood types and grades of plywood. The best plywood for making skateboards is 1/8″ Baltic or Russian Birch. Typically, Baltic Birch comes in 5′ x 5′ sheets in thicknesses from 1/8 to 3/4″. Home Depot, Lowe’s and Rona in Canada do not sell true Baltic Birch and even though the material is similar in look it is not suitable for board building. You may find Baltic Birch at local, independently owned lumber yards.

North America Plywood grades of lumber are usually not suitable for making quality skateboards unless you can find a full core maple or birch with little knotting or open voids within the cores.

Baltic Birch Plywood

Boards made with Baltic Birch usually start out as 1/8″ sheets 5′ x 5′ square. The core of quality Baltic Birch is solid. Any internal knots have been punched out and filled with a birch plug. For board building, sheets are cut into rectangles a little larger than the profile of the finished deck. The sheets are stacked, glued then pressed over or inside a mold. Once dry, the material conforms to the shape of the mold.

This is a grading chart for Baltic Birch

Pros

Cons

Bamboo

Bamboo is a rapid growing grass that is marketed in North America in many forms. Generally what is used for making skateboards is sheet stock manufactured for cabinets and wall paneling. It comes in a variety of configurations and thicknesses which range from 1/8″ to 3/4″. Usually the sheet sizes are 4′ x 8′.

Bamboo sheet stock is made up of many thin lengths of bamboo glued together, edge to edge to make 4′ x 8′ panels. These panels are then milled flat and laminated on top of one another to produce different thickness configurations. You can see the individual pieces of bamboo and the laminating in the picture here.

Bamboo is marketed as a green product but there are many who say it is not. Here are some sites that are worthwhile reads on this subject.

Processing bamboo is very labour intensive. Here are some videos that show how it is processed into sheet materials

Pros

Cons

** Since this article was originally posted, Roarockit now stocks 1/16" bamboo created specially for skateboard building and imported from a mill in China.

1/16″ Maple Veneer

The best maple for skateboards is grown in northern Canada and is called Sugar Maple (Acer Saccharum).

Studies have shown that the longer the winter and the colder the climate, the tighter the growth ring will be because of the short growing season.

The farther north the tree is harvested, the harder the Sugar Maple will be.

Grain Direction Within a Skateboard

Roarockit veneer comes from a northern most mill that produces skateboard veneer for many of the large skateboard companies.

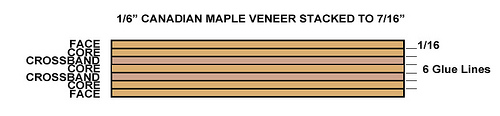

Maple veneers for skateboards come in 3 configurations;

Face – This is the veneer that is intended for the outside layers of your deck. There are no blemishes, stains or knots and it is cut in the long grain direction.

Core – Also long grain direction, this veneer is intended for the inside of the deck as there may be some solid knots and staining. Sometimes we find interesting looking core sheets, so pretty that they look great on the outside of a custom board!

Cross grain – This material is the same as the core but is cut in a cross grain configuration. Normally there are two cross grain layers in a board and is intended to give the board strength across its surface. Sometimes smaller pieces are stitched together in the veneer mill to make up the larger rectangles. This does not hinder board strength.

Rotary Cut

Sugar Maple for skateboards is almost always rotary cut on a large lathe-like machine that peels the veneer off a log at varying thicknesses. Normally this is 1/16″ thick but it can vary depending on the manufacturers specifications.

Moisture content

The moisture content when shipped from the mill should be between 7 to 9%. Depending where the veneer is destined, moisture content may change during shipping. If the veneer is exposed to high or low humidity it will acclimatize to its surroundings.

Maple veneer is very prone to expansion and contraction when exposed to moisture content in the air. I have seen our 48″ long cross grain veneers expand up to 3/4″ when sent to a tropical climate. It is important to store your veneers in a cool, dry place away and from any heat source like a sunny window or radiator.

The cross grain veneers are often sent to us from the mill stitched together. This is where smaller pieces are cut and glued together to make one 48″ piece. Veneer mills do this to be efficient and environmentally responsible by making use of all the wood cut from the log. Usually the glue joints are stronger than the surrounding wood. If one of the glue joints break it can be easily fixed by slicing with a sharp utility knife a across the veneer, creating a new edge on both pieces. Re-glue them back together using masking tape to hold the joint until the glue dries. Here is a video showing how this is done.

1/16″ maple veneers are easily cut with a sharp utility knife. Draw a straight line on the wood with a long ruler and score the wood with the utility knife three times. Bend the veneer against an edge of a table and it should easily break along the line you have scored with the knife. Check out this video.

Pros

Cons

1/16″ Birch Veneer

This is a new product offering and exclusive to Roarockit. It is designed to give board builders more choices to experiment with.

Grown in Canada, 1/16" solid birch veneer is as flexible as bamboo, without the high carbon cost. Read all about it in this these posts!

Colored Maple Veneer (Dye-Infused)

Colored veneers can be used to enhance the look of a board. Placing a layer of dye-infused veneer into your stack will give the board a colored line at its edge or use as a top or bottom layer that can be painted afterwards.

The advantage to infused veneers is that the color goes right though the sheet and cannot be sanded away.

Infusing veneers cannot be done by hand applying stain to wood. A pressure chamber is required to infuse the dye into the wood. Soaking veneer in a pan of dye will not achieve the desired results, as the interior of the wood will remain its natural color.

Roarockit stocks a selection of dye-infused maple, in both street deck and longboard sizes as well as a random Sampler Pack with lots of colors but a smaller size sheet. Colors change regularly.

RockitLam (Plastic Laminate)

Plastic laminate was invented by the Formica company in 1912. It is composed of many layers of resin-impregnated craft paper and a layer of Melamine resin. The top decorative layer can have a texture pressed into it and also be printed. In Canada, Arborite, a similar product, was invented in the 40’s.

Our 1/32″ thick material weighs about the same as a same-size sheet of 1/16″ maple veneer. There are considerable advantages to using plastic laminates as either a bottom or top layer on a board. Plastic laminate will add considerable stiffness. It can replace a layer of veneer without adding extra weight to the board. It is waterproof and can easily be applied by using either Titebond III or epoxy glues. It is very scratch resistant and if primed, can be painted or printed on.

We stock RockitLam in 12″ x 48″ sheets in many interesting colors and textures. (stock changes frequently) Builders may not be able to find a broad selection of this material locally in these small sizes. It is also thinner than what can be bought at building suppliers.

There are two tutorials on working with this material: see gluing RockitLam and also priming and painting RockitLam. Both tutorials are a must read!