Skateboard Presses

There are many different types of presses that can build a skateboard.

Depending on the choice of wood, there are pros and cons to each type of press.

Roarockit Thin Air Press

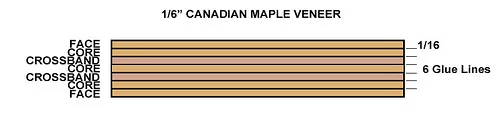

Most skateboards are laminated from thin sheets of 1/16″ veneer that are stacked one on top of another with glue between each layer. The veneers are then pressed in or on a mold. Usually the veneer in a seven layered skateboard is configured as shown below. Depending on the intended use of the board, extra layers can be added or subtracted from this configuration.

Hydraulic Press

2 part mold using a hydraulic press. This is what the industry uses. If you are manufacturing skateboards on a large scale where you have spent the R&D time creating a shape that you know will sell this is the established process to use.

Industrial Press

This press puts out a whopping 250 tons of pressure per opening and will hold 16 molds at a time and yield 80 decks in a 1 1/2 hour period.

Industrial Hydraulic Press

Pros

Cons

DIY Home Made Press

This press will make one skateboard at a time. Sometimes multiple boards can be pressed at once, depending on board design. This type of press uses a single or sometimes double hydraulic ram. Many small production skateboard builders use this type of press. Depending on the amount of ram pressure this type of press will exert around 175 PSI (Hydraulic ram pressure = 25 tons or 50000 pounds / square inches of your board (12 X 36 = 432) = a usable PSI of 115).

Franklin has a good calculator for the amount of head pressure needed for laminating skateboards of different sizes.

Jason at DIY Skate has a good tutorial for building this type of press.

Pros

Cons

Ribbed Press

This type of press is great for home builders who want to use local materials that can be bought from most hardware stores. It works great for building boards from plywoods like 1/8″ Baltic Birch. You will need a jig or bandsaw and an electric drill. Ryan Snider, RS Skateboards built this mold.

Chudibap has a great build tutorial on YouTube showing how to build this mold.

Pros

Cons

Dimm Press

A friend from Montreal came up with the idea of using foam in a simplified 2 part mold to press longboards. The “Dimm Press” is very popular with beginner board builders.

Pros

Cons

Rail Press

These types of presses are great for beginner skateboard builds using Baltic Birch plywood as they depend on the rigidity of the plywood to even out the amount of pressure needed to glue the materials together.

Most people use 1/18″ or 1/4″ plywood to build their boards from.

The material needed to build this board press with is easily found at any lumber store like Lowe’s and Home Depot.

Pros

Cons

Roarockit Thin Air Press Method

This is our patented method of using a one-sided foam mold in a vacuum bag to build a board. Typically this method uses a manual, electric or venturi vacuum pump as a vacuum source to evacuate air from a sealed bag forcing atmospheric pressure to act as a clamp to press multiple layers veneer together into a skateboard shape.

Shaping foam is a relatively simple process and one that has made it possible for builders to build complex shaped skateboards. There is a lot of information on this website, in tutorials that show all you need to know to get started.